Audits & assessments

Audits & assessments

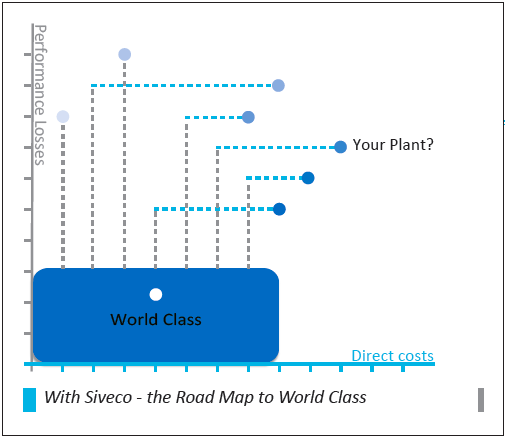

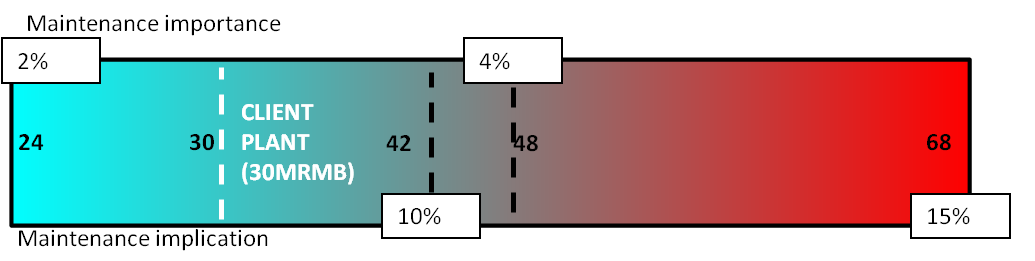

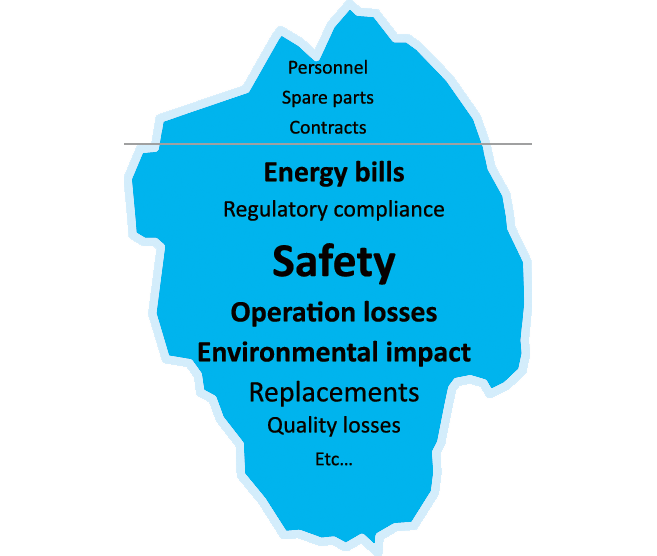

Companies tend to see maintenance as a necessary cost, often considered low in China (cheap labor, locally-made parts). Priority is being put on new investment, energy savings, safety, etc. seldom seen in relation to maintenance. Experience, on the contrary, shows that maintenance has a dynamic effect on the whole infrastructure. If maintenance is poor, the plant will never reach its full potential, safety risk will increase and the company will not be as profitable as it should be.

Maintenance improvement is often not about cutting budgets, but about improving effectiveness, reducing losses and preventing risks: indeed, our studies show that you can save more than 10 times more money by acting on indirect costs and losses, i.e. the impact of maintenance on the business. But: where and how? This is the question we can answer.

The Chinese market, in which our team has been active for over 20 years, presents its specificities. Its modern-time industrial development has long prioritized new construction, capacity expansion, rather than maintenance: the entire supply chain, including design institutes, contractors, equipment suppliers, service companies, the education system etc. was aligned accordingly. In the past few years, official studies have shown that most industrial accidents, safety and environmental problems were caused by technical management mistakes at either working level or top management. Similarly, authorities have identified higher lifecycle cost, in particular due to fast aging (early replacement) or equipment, in public facilities. This has prompted the Chinese government to increase regulatory pressure, a phenomenon that all companies operating in China have observed, and to generally promote a more risk-based approach to technical management.

Based on a unique experience combining both industrial maintenance expertise and consulting project in the past 20 years in China, Siveco China has developed a proven maintenance assessment methodology: an approach that has delivered results for many facility owners and operators in China.

|

The assessments are designed to answer such questions as:

|

|

The assessment is designed to address the company's strategy and top concerns, in line with ISO 55000 Asset Management standard, while adopting a very open wide-angle approach to ensure unknown issues can be identifies.

Our assessments are always tailor-made to each customer's specific case. We can however distinguish three types of assessments:

- Maintenance organization assessment – focus on the organization and its processes

- Maintenance system assessment – focus on your systems and their utilization

- Condition assessment – focus on the equipment itself and its condition

Often our assessments combine components from all three types above to answer the key questions:

1. Where do you stand?

- What is your situation now?

- Are you on top of your industrial risks?

- What are you getting for each RMB you spend on maintenance?

2. What could you gain?

- What direct costs could easily be cut?

- What would performance improvements deliver to the bottom line?

- What risks can be prevented, controlled or mitigated?

3. How can you achieve your goals?

- We provide prioritized action plans

- A guide for implementing the action plans

- Based on a knowledge-base of best maintenance management practice

Siveco China assessments always involve active cooperation between the customer's and Siveco China teams, based on the following working principles:

- A dedicated expert on your project

- An on-site action focused on your main requirements, driven by a Siveco China project manager, assisted by maintenance engineers

- A partnership approach of our work: we recommend efficient, long-term solutions, and prepare your teams in a self-working organization

Confidentiality and independence: Siveco China will sign Non-Disclosure Agreements as required by customer, managed under our ISO 9001:2015 quality system.

Safety is non-negotiable: all Siveco China employees will wear the necessary personal protection equipment when working on site.

Note that all Siveco China projects are offered on a fixed price basis for the scope defined in an agreement.

The Siveco China assessments are based on a standard assessment methodology that we have used in many projects across China, and on the professional expertise of our team members, always capable to adapt and improvise if needed.

Whenever applicable, European and IEC standards are used (alternatively, customer can request specific standards to be applied), chiefly the ISO 55000 Asset Management standard (also known as the GB/T 33172-2016 series in China).

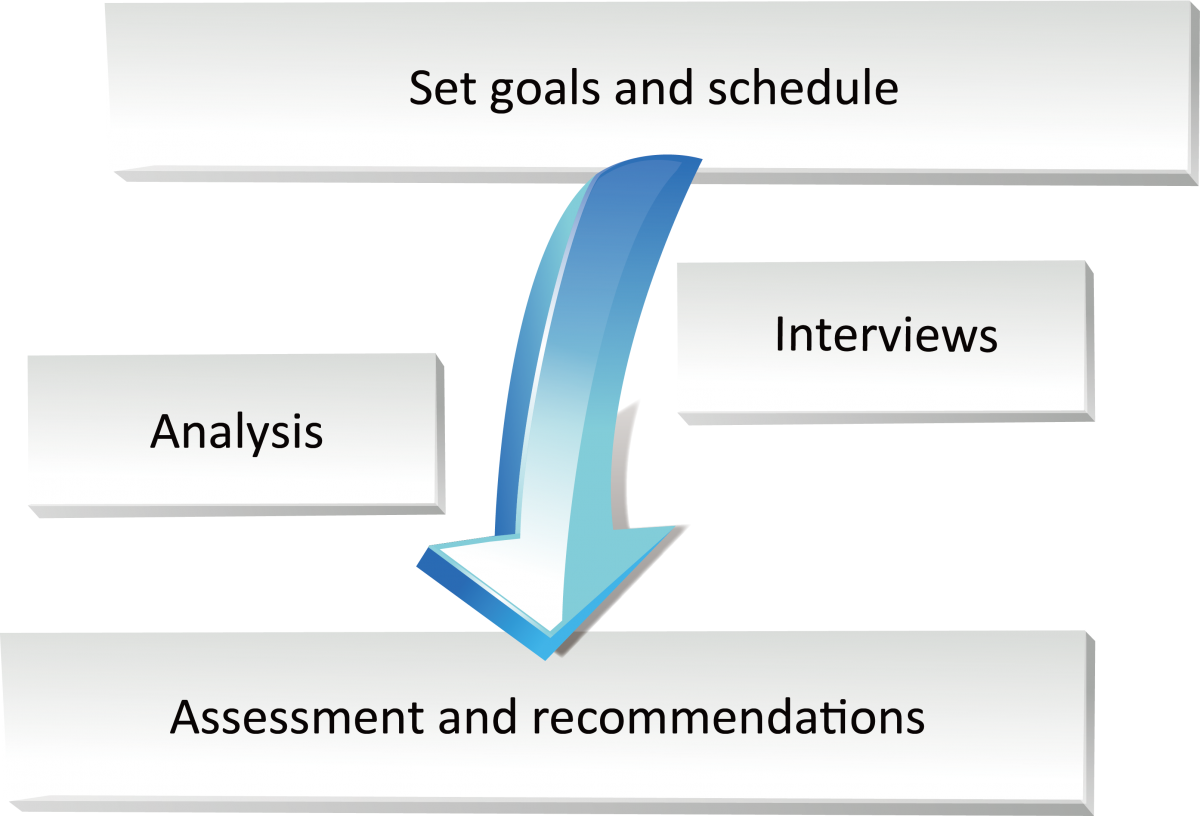

Assessments always comprise three main phases as shown in the figure:

For the assessment, standards of interest include:

- ISO 55000 Asset Management – Management Systems, as a risk-based framework for maintenance.

- EN 13460: Maintenance – Documents for maintenance.

- EN 15341: Maintenance – Maintenance key performance indicators, as offering a user-friendly collection of standard performance measures.

- CEN/TR 15628: Qualification of maintenance personnel, for HR/skills management aspects.

- ISO 14224 Collection and exchange of reliability and maintenance data for equipment, addressing data needed to manage maintenance and offering strong support for the design of a maintenance system.

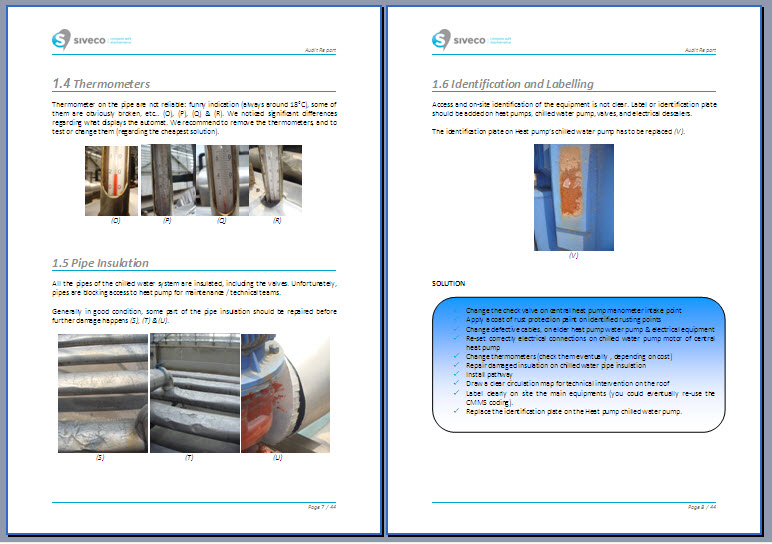

The main deliverables for the assessment are:

- Detailed assessment report (completed Excel document and analysis report, which would include, depending on the scope of assessment, pictures, work processes maps, etc.)

- Recommendation report with related action plan. Recommendation report could include ROI estimates (if financial data was made available to Siveco China) or other improvement metrics.

- Optionally, the above data and action plans in advanced electronic format (for example to be managed in a CMMS) with possible follow-up services by Siveco China.

The report with our recommendations will be presented to the management team at the end of the project, after which discussions will take place. A final conclusion report will be drafted at the end of the session.